- G code cnc simulator software software#

- G code cnc simulator software code#

- G code cnc simulator software professional#

- G code cnc simulator software free#

- G code cnc simulator software mac#

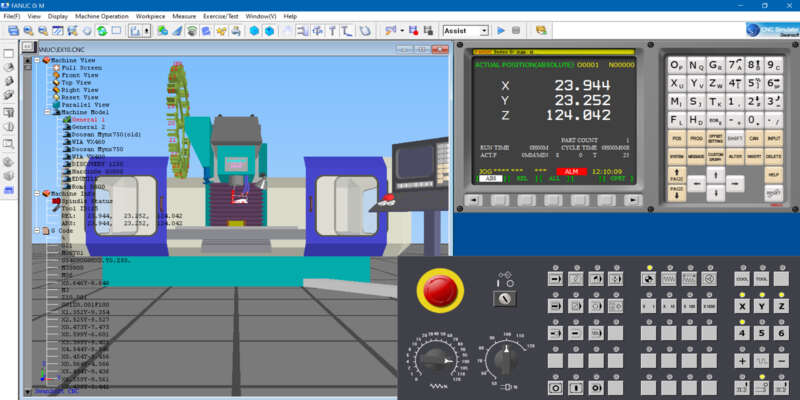

CNC.NC simple requirements such as circles and lines, you can easily create G-Code manually. There are many types of G -Code files, the most popular G-code file types are. It directs the machine on the speed and depth of the movement. This also provides the direction in which the machine should move. A G-Code is used to instruct and control automated tools.

G code cnc simulator software code#

There are G-Code editing programs that can be used to convert G Code to Conversation CNC or to simulate the G -Code itself.G-Code is one of the most popular and widely used programming languages. Eventually, this expands the scope of production and manufacturing.Some CAM programs can directly edit the CAD file and generate corresponding G-Codes using CAD Editing Programs. It can eradicate the gap between design and manufacturing by the appropriate realization of drawings, designs, and models and provide the anticipated output.

G code cnc simulator software software#

This software uses the models and assemblies created in CAD software to generate toolpaths that drive machine tools to turn designs into physical parts. CAM software can generate G- Code from a CAD design or an image. This process is done with the help of CAM software which stands for Computer-Aided Manufacturing. This is the language used in CNC machining. Acquired by Stsratasys, they now have two products: GrabCAD Workbench and GrabCAD Print Step 2: Convert the vector file to G-Code using Computer-Aided Manufacturing (CAM) software.įrom CAD program, the vector file is converted to G -Code.

G code cnc simulator software professional#

It is a platform where people from all walks of designing like woodworkers, architects and professional designers can work together and download a ton of different CAD files. It provides many options in CNC Export functions such as Z settings, Scale settings, Arc and circle rotation, and G-Code Bezier options.īonus: GrabCAD has an interesting feature called Workbench that allows user to collaborate on a CAD design with others. Scan2CAD gives you flexible licensing and 24/7 support. This is a great source for CAD, CAM, and CNC. The Scan2CAD has more to add compared to other options on the list. The main limitation of this freeware is its finite source collections.

G code cnc simulator software free#

The top free DXF websites are My DXF, Scan2CAD, Vector Ink, Ponoko, SignTorch, Free DXF, etc. These are easily available in the market. If you do not want to create a design by yourself, you can try ready to cut DXF designs as an alternate option. It not only provides 2D drawing but also helps to create 3D models. These free CAD software are much simpler and easier to use. Top free Drawing Exchange Format (DXF) file sites are

G code cnc simulator software mac#

You can open DXF files in Mac and Windows OS. This is the file extension for a graphic image and enables data interoperability between CAD and other programs. The most common vector file format is DXF. You can create designs and vectors using CAD software where CAD stands for Computer Aided Design. To get started with the design stage, you require a vector file(A vector file has coordinates for the tools to move in different axis). Step 1: Create a vector file (DXF) using a Computer-Aided Design (CAD) software. Step 3: Use CNC software to process the G-Code to run the machine in the desired manner.

Step 2: Convert the vector file to G-Code using Computer-Aided Manufacturing (CAM) software.5 Best CAD software that support CNC Machining.Top free Drawing Exchange Format (DXF) file sites are.Step 1: Create a vector file (DXF) using a Computer-Aided Design (CAD) software.We have curated the article from our own experience and research which will enable you to find the best software for CNC machine but also multiple different options which are both paid and free. Since we know that a lot of our readers are newbies who are looking for the best woodworking tools and recommendations.

G- Code is used to communicate with the CNC machines and enables the machine to move in the desired pattern. This design is converted to G-Code using CAM program. You first need a design in a vector file, unless you already have G-Code. These formats can be used across platforms.įrom design to manufacturing stage, a CNC machine uses three different kinds of softwares namely, CAD, CAM and CNC controller software. In CNC machining, the commonly used file formats are STEP and IGES. It is capable of controlling the speed of rotation and rate of the movement. G- Code is programmed in such a way that it controls the movement of a machine by adjusting the position of x, y, and z-axis. Alternate to G-Code, there are Heidenhain and Mazak also in use. The primary CNC programming language is G-Code. Each part of the machine requires its own CNC program. A Computer Numerical Control (CNC) software enables to create programs to run a machine tool.

0 kommentar(er)

0 kommentar(er)